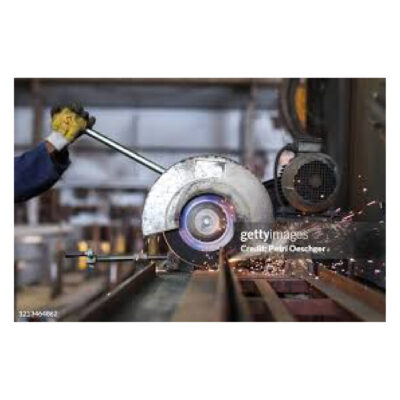

Welding is a fabrication process that joins sheet metal parts by melting the base metals and fusing them together, often with the addition of filler material. It is used to create strong, permanent joints and is essential in constructing frames, brackets, enclosures, tanks, and structural components in sheet metal assemblies.

WhatsApp us

Welding

Welding is a fabrication process that joins sheet metal parts by melting the base metals and fusing them together, often with the addition of filler material. It is used to create strong, permanent joints and is essential in constructing frames, brackets, enclosures, tanks, and structural components in sheet metal assemblies.

Availability:

In Stock

SKU:0096

Material Thickness - Range 0.8 mm to 12 mm (varies by welding method)

Welding MethodsCommonly Used in Sheet Metal:

- MIG (Metal InertGas) - Fast, suitable for mildsteel, stainless steel, and aluminum

- TIG (Tungsten Inert Gas) - Precise, clean welds, ideal for thin sheets and stainless steel

- Spot Welding - Resistance welding; used for overlapping joints in thin sheets

- Stick (SMAW) - Less common for thin sheets, more for structural or repair work

- Materials - Mild steel, stainless steel, aluminum, galvanized steel

- Joint Types - Butt, lap, corner, edge, and T-joints

- Weld Strength -High; dependent on process, penetration, and filler metal

- Surface Finish - May require grinding or polishing for appearance or prep for painting

- Heat Affected Zone (HAZ) - Present; may alter metal properties (TIG = lowest HAZ)

- Distortion Control -Fixturing and proper welding sequence required for thin sheets

- Best For - Enclosures, boxes, tanks, cabinets, frames, supports

- Automation -Manual, semi-automatic,and fully robotic welding options available

Be the first to review “Welding” Cancel reply

Reviews

There are no reviews yet.